How the Calgary Composting Facility works

How the composting process works

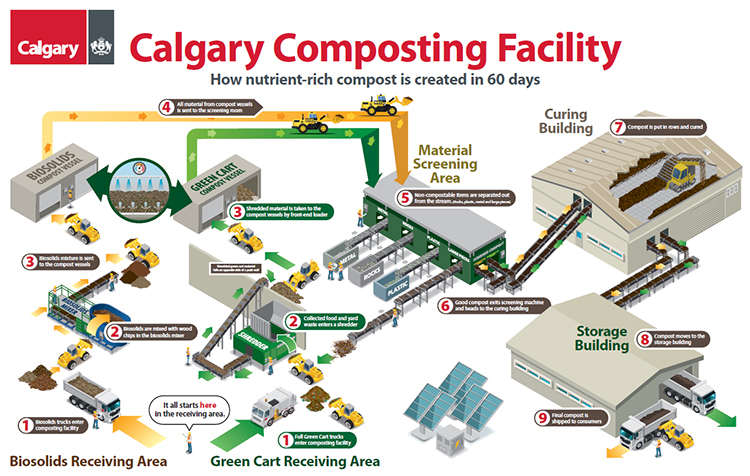

Although the science is similar to backyard composting, here's an in-depth look at how industrial scale composting is different and why you can compost so many more materials with your Green Cart. From start to finish it takes approximately 60 days to produce nutrient-rich compost.

Two varieties of compost

The composting facility produces two compost varieties from two different sources. They are processed separately. They are:

- Peak Compost: A Category A compost made from Green Cart food and yard waste; and

- Peak + Compost: A nutrient-rich biosolids based compost that meets Category A criteria.

Both add valuable nutrients to the soil. The composting process and testing for each variety is the same.

Please click the image to view a full size picture

The composting process

Step 1 - Food and yard waste is dropped off

Food and yard waste arrives by trucks to the composting facility. Material is emptied out onto the tipping floor.

Step 2 - Shredding the material

The material is then moved onto shredder equipment. The food and yard waste material is shredded to open up bags and break up larger materials to create a recipe for optimum decomposition.

During the winter months dewatered biosolids are brought to the compost facility. Biosolids are a nutrient-rich, organic material produced by advanced wastewater treatment. Biosolids are blended with various types of wood chips to create the ideal mix to enhance the composting process.

Biosolids material and Green Cart food and yard waste are kept separate.

Step 3 - In-vessel composting

The material stays in the composting vessels for 21 days. During this time the pipes that extend beneath each vessel pump air into the material, keeping the microorganisms that break down the material active. Vessels are monitored for things such as temperature, moisture content and oxygen levels. This keeps the decomposition process running smoothly.

- Odour control

Odour management is one of our main priorities. We've invested in odour control systems to filter them out. Large biofilters are used to reduce odours before exhausting air from the building. Air from both the active composting and curing phases is directed through the biofilters. - Eliminating pathogens

The compost pile reaches temperatures of at least 55 degrees Celsius for at least 3 days in a row. These sustained temperatures are difficult to achieve in backyard composters. This step is important because it kills off pathogens like e-coli and salmonella that might be found in materials like uncooked meats and pet waste.

Step 4 and 5 - Screening

All material from the compost vessels is sent to the screening room.

The compost is then screened for non-compostable materials like plastic, metal, large objects etc. that will be taken to landfill. This helps to remove contaminants in order to produce top quality compost. Learn more about why contamination in the carts is a problem.

Step 6, 7, and 8 - Curing, cool down and storage

After screening, the compost material enters the curing building where it remains for another 21 days. The material is turned over and mixed every five days to introduce oxygen and encourage further decomposition. Pipes in the floor draw air in and through the material to further enhance break down. After curing, the material is moved to the compost storage facility.

Final product testing

The composting facility produces Category A compost that is safe to use anywhere, including farms, gardens, parks and nurseries.

To ensure it meets this compost standard, samples are sent to a Compost Quality Alliance (CQA) accredited lab for analysis to ensure it passes the criteria set by the Canadian Council of Ministers of the Environment.

Sale of compost

Once certified as Category A, the compost is ready for distribution. Compost is a sustainable, nutrient-rich soil amendment used to enrich our soils.

The majority of the finished compost is sold in bulk to companies such as landscape soil blenders and compost baggers. The proceeds from the sale of the compost help reduce the processing cost and lower the Green Cart program fee.

A portion of the finished Category A compost from Green Cart is made available to the community for free. This includes being made available for community gardens and through select giveaway days to the public.

Composting Facility Expansion

Anaerobic digestion

The expansion will see exciting new technology added to the facility operations. An anaerobic digestion system will complement the existing in-vessel composting process allowing the facility to process even more material and capture bio-gas that will be upgraded into a renewable natural gas .

In this process, some food and yard waste materials will continue to go to the composting vessels (step 3). The rest of the material will be put into the anaerobic digestor. Materials will stay inside the anerobic digestor for approximately three weeks.

Two products will be produced through the anerobic digestion process:

- Bio-gas: gas captured from the anerobic digestor

Since the anerobic digestor is fully sealed, the food and yard waste material is breaking down in the absence of oxygen which results in the production of bio-gas. The bio-gas will be captured, upgraded into renewable natural gas and marketed as a fuel. The revenue generated from the sale of the bio-gas will be used to support the Green Cart program. - Digestate: the broken down food and yard waste from inside the anerobic digestor

Once the material inside the The anaerobic digestion digestor has broken down and the bio-gas captured, the resulting digestate can be mixed with incoming food and yard waste material and composted to produce nutrient rich compost. As the digestate is already mostly broken down, it will require less time inside the composting vessels to finish composting – approximately two weeks.

Why anerobic digestion?

- By breaking down material first in the anerobic digestor, it will require less time in the composting vessels. This will increase the facilities overall capacity to make use of existing buildings and spaces.

- Producing and capturing the bio-gas will result in lowered greenhouse gas emissions.

- Increased opportunity for revenue generation through the sale of bio-gas.

Book a school tour of the composting facility or find other education resources at Waste & Recycling Educator Resources.