Trains

Introducing the Urbos 100

The Green Line’s Urbos 100 Light Rail Vehicles (LRVs) mark an exciting new era for Calgary’s transit system. They are the first low floor vehicles to be used in Calgary, and the first time an Urbos 100 model will be used in Canada.

Manufacturing of the new LRVs began in 2025.

Read on to learn more about:

Experience a 360 Degree VirtualTour of the Urbos 100

Step inside Green Line's LRV mock-up! This life-size model is 12 metres long, which represents just over a quarter of one vehicle length.

Train First, Infrastructure Second

Green Line was designed in a way that is different from many other Light Rail Transit (LRT) projects: we designed the trains first and are building the rest of the system to fit the trains. This ensures that all the infrastructure, including tracks, stations, tunnels and bridges, is built around the specifications of this train.

Procuring the trains first reduces risk to the overall project. The LRV design was completed in September 2023, in advance of finalizing the main infrastructure design. This reduces uncertainty around how the train interfaces with the infrastructure, as the LRV design is used to inform many aspects of the system.

Differences Between Trains

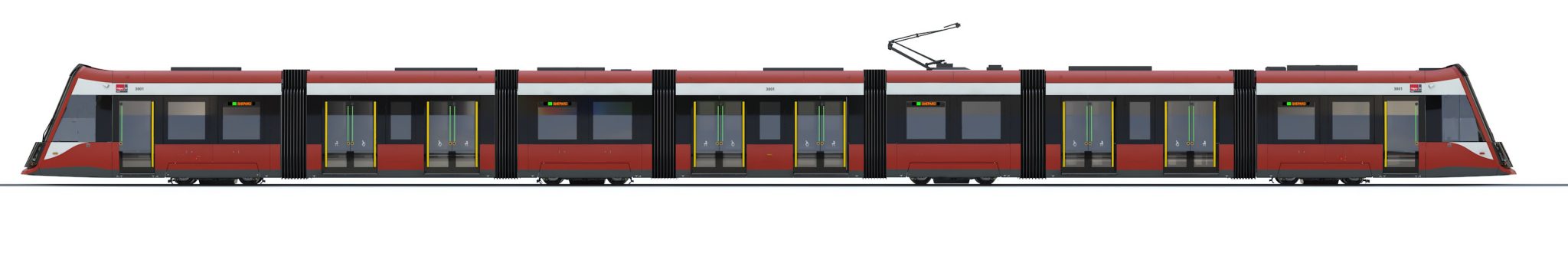

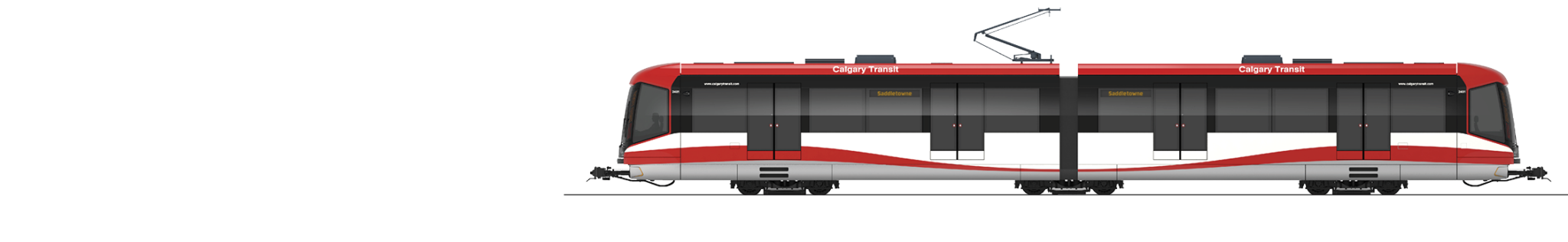

Green Line will operate 2-car trains, which are approximately equal in length and passenger capacity to 3.3 vehicles that are currently used on Red and Blue lines.

Green Line LRV

Red and Blue Line LRV

| Green Line: Urbos 100 | Red/Blue Line: Siemens S200 | |

|---|---|---|

| Platform type | Low Floor | High Floor |

| Maximum passengers | 288 | 181 |

| Length | 42 metres | 26 metres |

| Seats | 73 | 61 |

| Standing spaces available | 215 | 120 |

| Doors | 8 | 4 |

| Persons with reduced mobility spaces per car | 3 | 2 |

Train Image and Video Gallery

Low Floor Trains

Low floor Light Rail Vehicle (LRV) technology has been the standard in Europe, Asia, Australia and New Zealand for decades. It’s now becoming the choice for new Light Rail Transit (LRT) systems across North America because of the many benefits it offers.

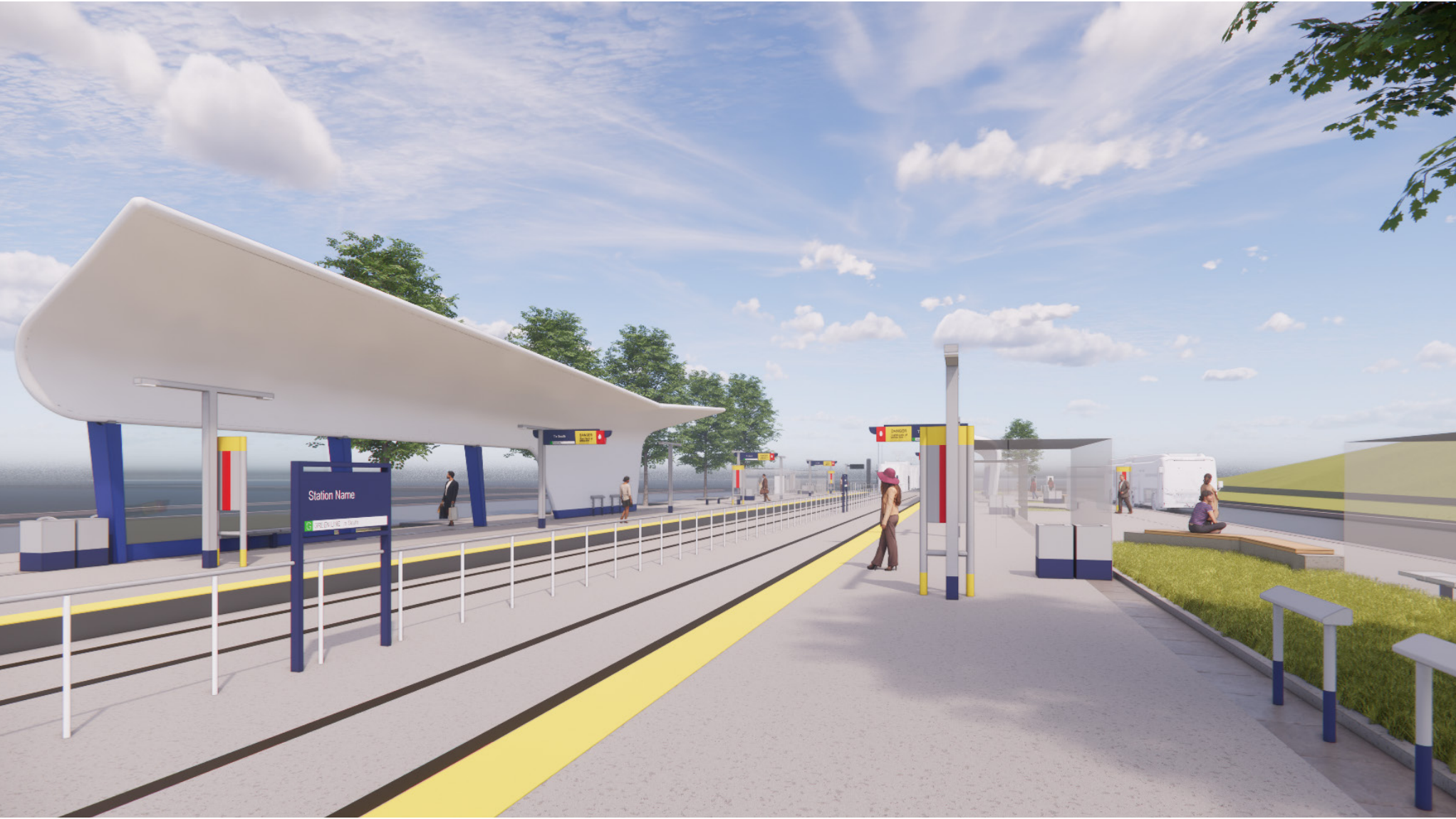

Lower Platforms and Improved Accessibility

- When standing in a high floor train you are approximately 1 metre off the ground. Inside a low floor train, you are 0.34 metres off the ground, which is slightly higher than a sidewalk curb.

- Lower platforms make it easier to access trains because stairs, long ramps and escalators are not necessary for street-level stations.

- The low floor trains also offer many accessibility benefits.

Station Designs that Integrate Easily Into the Surrounding Area

- Low floor transit systems can allow for station designs that are smaller, simpler and integrate easier into the community than high floor systems.

- Stations at street-level don’t require large station structures, so the footprint of the station tends to be smaller.

- Access to street-level stations is seamless from sidewalks and pathways.

Comparison of street-level stations on low floor and high floor LRT systems

Low floor

A typical street-level Green Line station is easy to access and integrates seamlessly into the urban environment.

High floor

To access the platform at Sunnyside Station multiple stairways and ramps are required.

Cost Savings

- Low floor transit stations at street-level usually require less infrastructure than high floor stations do, resulting in overall cost savings during construction.

- Many of Calgary Transit’s existing stations require bridges to access stations, and escalators, elevators and stairs to reach the platform. These make the stations more expensive to build.

- Repairs to elevators and escalators are costly and time intensive, and impact accessibility when they are out of service.

Enhanced Vehicle and Pedestrian Safety

- A hood covers the train coupler (the mechanism that connects train cars). This reduces injuries in collisions with vehicles or pedestrians.

- The curved front of the vehicle and skirting along the base is designed to limit pedestrian injuries.

- In the event of a collision with another train or a road vehicle, the front of the vehicle is designed to absorb the energy of the collision.

Design Safety & Accessibility

Low floor trains offer many safety and accessibility benefits.

Light Rail Vehicles (LRV) Safety Features (Interior)

1. Emergency touch strips – Allows passengers to initiate an emergency if they are not standing next to a passenger emergency intercom. Touch strips are silent alarms that don’t draw attention when touched. The operator will be alerted, and the two nearest cameras will be activated for the operator to view and assess the situation.

2. Security cameras – Five external, two in the operator’s cab, and eight in the passenger area. Footage is recorded on a local network video recorder and can be viewed live from the operator’s cab and remotely at the Operations Control Centre.

3. Door status indicators – LED lights on the doors turn green to indicate door availability and platform side. Red lights indicate the door is unavailable.

4. Emergency intercoms – Eight per vehicle, which allow passengers to communicate with the operator and/or staff in the Operations Control Centre in an emergency.

Light Rail Vehicles (LRV) Safety Features (Exterior)

5. Carbody design and crashworthiness – A curved hood covers the train coupler (the mechanism that connects train cars). This reduces injuries in collisions with vehicles or pedestrians. In the event of a collision, the car body is designed to absorb the damage.

6. Operator on board – at all times.

7. Heating, ventilation and air conditioning – Three units per vehicle to keep passengers comfortable.

8. Three braking methods – For guaranteed braking under all conditions.

LRV Accessibility Features

1. Double doors – Three sets of spacious doors for people with mobility aids or strollers to enter/exit.

2. Easy to board – LRVs are level with station platforms and there are no steps.

3. Assistive listening T-coil – Allows hearing aid users to directly connect their hearing aid to the emergency intercom system to provide clearer listening.

4. Button to extend door opening time – Pressing this button allows passengers to extend the nearest door’s opening time, providing additional time to depart the train.

5. Designated mobility aid areas – Three per vehicle for people with mobility aids, strollers or bikes. These areas are located between each set of double doors.

6. Spacious interior – Room to easily move around.

7. Passenger information displays – 12 per vehicle to display time, next stop, transit connections and other information for passengers.

Manufacturing & Testing

Manufacturing of the Urbos 100 light rail vehicles began in 2025 at CAF’s production plant in Spain. A total of 28 vehicles will be built for Phase 1 of the Green Line.

About the Train Manufacturer

After a competitive procurement process, Construcciones y Auxiliar de Ferrocarriles (CAF), a Spanish train manufacturer, was awarded the contract to supply Green Line with 28 low floor Light Rail Vehicles (LRVs). The contract also includes the tools and support for operating and maintaining this new fleet and an option to purchase additional vehicles to support the long-term vision for the Green Line.

(Image: The Budapest Tram is another Urbos 100 model by CAF)

Manufacturing Process

- Train assembly takes place in the CAF production plant in Zaragoza, Spain.

- Trains are manufactured in a production line, similar to cars. However, unlike cars, there is little automation (robots) involved in the process.

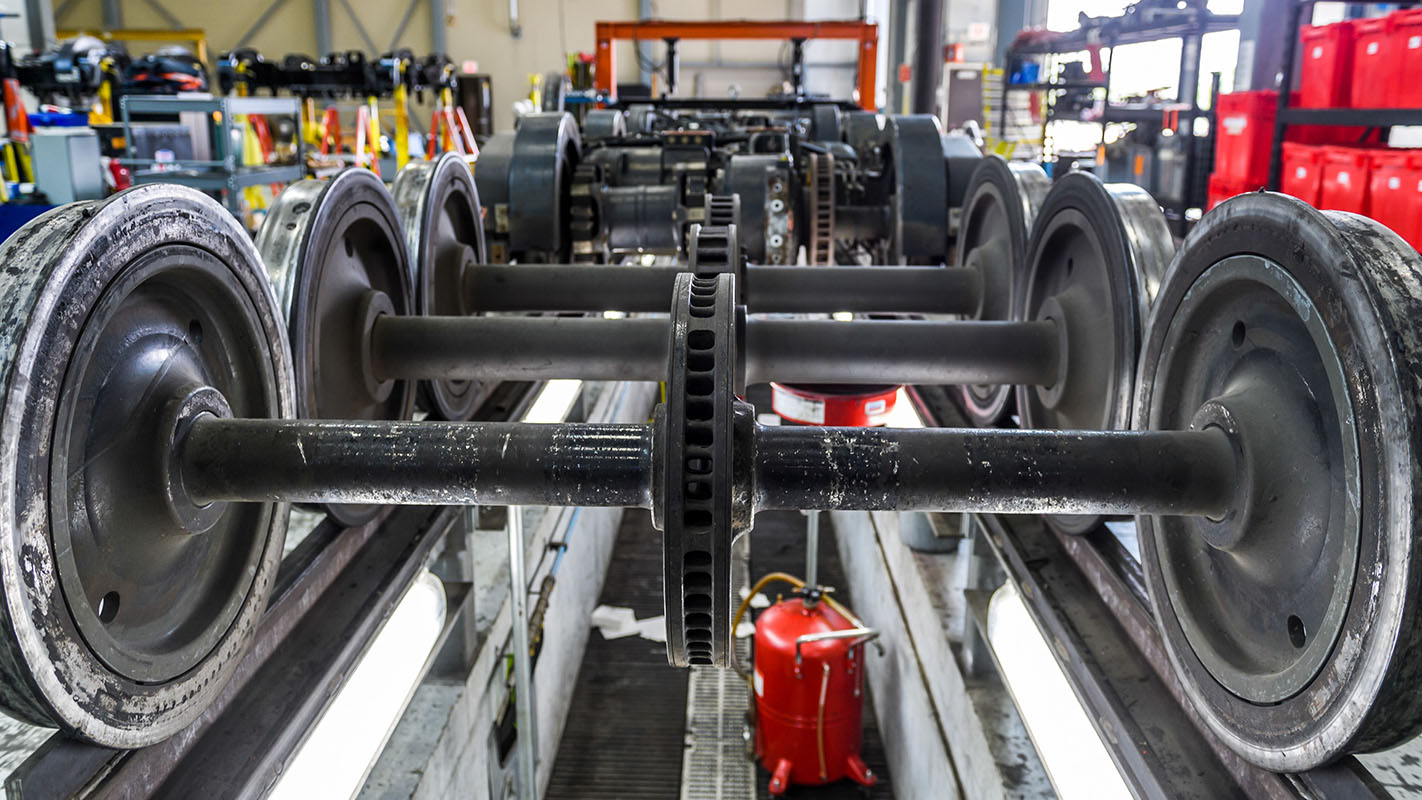

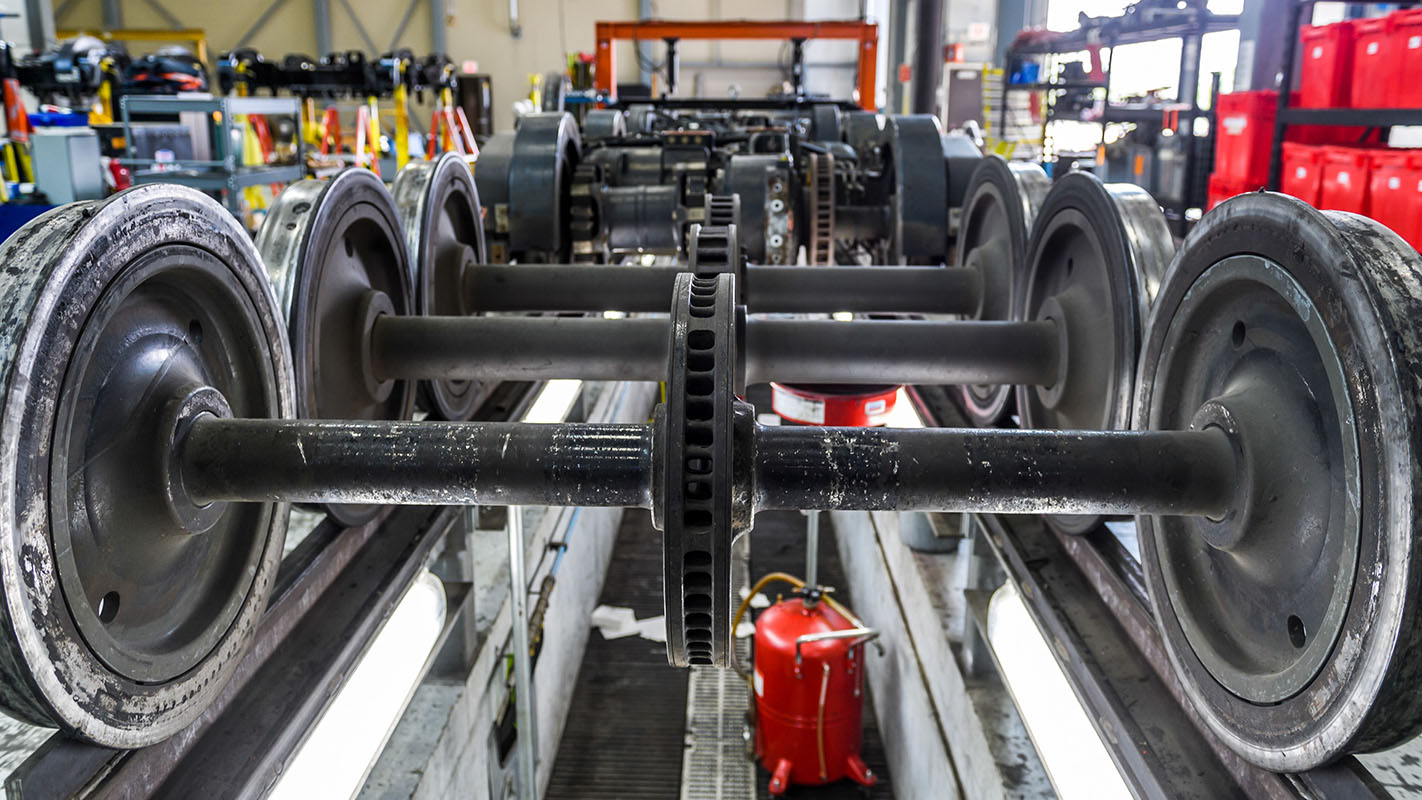

- Some components are built by CAF and their subsidiaries including the wheels, wheel sets and bogies (a chassis under a train car that holds the wheels, axles and suspension system).

- Most components are procured from sub-suppliers, then installed on the trains.

(Image: LRV wheel sets and parts at Calgary Transit’s maintenance and storage facility)

Testing

- There are multiple stages of testing (component level, system level and train level) to ensure the train will perform as designed.

- The individual train components (such as traction motors, batteries and pantographs) will be tested and validated by the sub suppliers.

- Once CAF and Green Line verify and approve the test results, the components are delivered to CAF and assembly can begin.

- Once all components are installed, tests will be undertaken to ensure all systems work together and the train functions as one unit.

- When the trains arrive in Calgary, functionality will be re-verified and they will be tested for acceleration, braking, going through tunnels and pulling up to station platforms. Radio systems and technology will also be tested and verified.

Cold Weather Testing

Climate chamber testing is a tool we’re using to ensure the new trains can perform in Calgary’s winter conditions. This is a stress test for LRVs, which closely emulates real climate conditions. The first manufactured LRV will go inside an indoor climate chamber where humidity, temperature and other conditions can be adjusted. The temperature will be lowered to -40 degrees Celsius, to test:

- Insulation of the vehicle body.

- Accumulation of ice and snow in the door areas.

- Functionality of window wipers, windscreen heaters and doors.

- The braking system in extreme cold, snow and more.

Calgary Transit has 40+ years of experience operating LRVs in cold weather. The lessons they have learned, plus additional cold weather testing, will ensure Green Line’s trains can handle the cold and snow.

Delivery of Trains

- 28 trains will arrive in Calgary as finished products.

- Trains will be delivered to the Maintenance and Storage Facility via ship and rail.

- Each vehicle is 42m long, making it too large to ship in one piece. Prior to delivery the vehicles will be disconnected into three parts, which will be re-assembled in Calgary.

(Image: In 2016 Calgary Transit’s newest LRVs were delivered to Anderson Garage via the Canadian Pacific Railway)