The Water Treatment Process

Creating high-quality drinking water for over one million Calgarians

We work to make sure everyone has a safe and reliable supply of drinking water. Calgary's water treatment plants, Glenmore and Bearspaw, operate 24 hours a day, 365 days a year.

Operators, electricians, maintenance, the laboratories and administrative employees all work together to ensure the integrity of our drinking water.

The plants can produce a combined total of 950 megalitres of drinking water per day, enough to fill the Calgary Saddledome nearly three times.

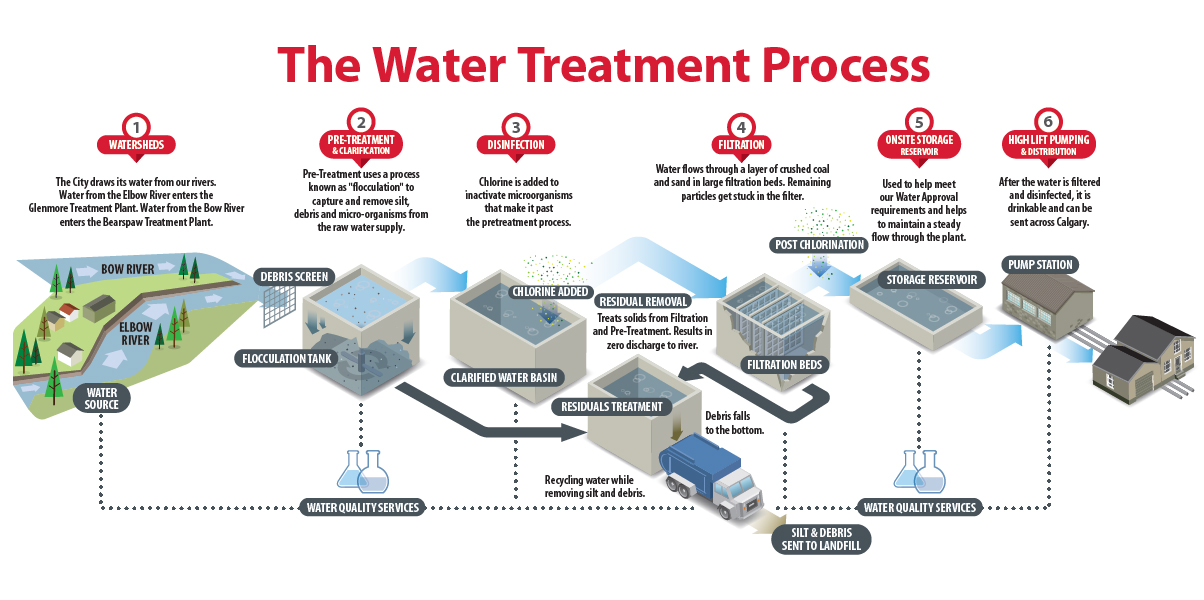

1. Watersheds

The Bearspaw Water Treatment Plant draws water from the Bearspaw Reservoir on the Bow River, while the Glenmore Water Treatment Plant draws water from the Glenmore Reservoir, which is fed by the Elbow River. To learn more about where our water comes from, visit Calgary's Water Supply.

Raw water travels through coarse screens to remove large debris, such as leaves, before it's pumped to the plants using energy generated by low-pressure pumps.

These pumps provide the energy needed to drive the water to the start of the water treatment process. From the Pre-Treatment Facility water flows by gravity until it is reaches the High Lift Pump Station.

2. Pre-treatment and clarification

Pre-treatment uses a process known as “flocculation” to capture and remove sediment, debris and micro-organisms from the raw water supply.

Raw water enters large mixing tanks where aluminum sulphate, sand and polymer are added which attach to particles in the water creating what is known as “floc”. This makes the particles heavy, causing them to settle to the bottom of the settling tank.

The resulting clarified water moves on to a Clarified Water Basin, while dirty water at the bottom of the tank is pumped to a Residuals Treatment Facility. At this stage 99 per cent of sediment has already been removed from our drinking water.

Residuals treatment

Silt and debris from the pre-treatment and filtration process is sent to the Residuals Treatment Facility. This part of the plant acts as a giant strainer, removing as much water from the silt and debris as possible before recycling the water back to the start of the pre-treatment process.

Strained silt and debris is eventually collected and de-watered before being sent to City landfills.

The Residuals Treatment Facility reduces The City’s operational impact on the environment. Our ecosystem benefits greatly when silt and debris go to the landfill instead of back into our rivers.

In addition, recycling water within the plant has allowed The City to reduce the amount of water withdrawn from the river system by up to 10 per cent.

3. Disinfection

Clarified water enters the Clarified Water Basin, where a small dose of sodium hypochlorite (chlorine) is added.

The Clarified Water Basin provides enough time to disinfect the drinking water, killing micro-organisms and viruses that can cause disease.

4. Filtration

Filtration is the final step in removing any remaining silt, debris and micro-organisms from our drinking water. Large filtration beds allow water to flow through a layer of crushed coal and another of sand. Any remaining particles get stuck in the small spaces between particles of coal and sand.

To prevent the filters from becoming clogged with these particles, the filter is cleaned every 60 - 72 hours by a process called backwashing. A large pump pushes clean drinking water backwards through the filter. The stuck particles are loosened and carried away to the residuals treatment facility, leaving the filter clean once again.

5. Onsite storage reservoir

The onsite reservoir is used to balance high water demands with plant production levels to help maintain stable treatment processes.

It is also used to allow sufficient contact time with the sodium hypochlorite to ensure complete disinfection of treated water before it is pumped to the distribution system.

6. High-lift pumping and distribution

After the water is filtered, it is drinkable and can be sent across Calgary. Before the water is pumped off-site, another dose of chlorine is added in a process called post-chlorination. This ensures it remains drinkable on its journey through the distribution system to customer homes and businesses.

High-pressure pumps move the water from Glenmore and Bearspaw to supply the city’s distribution system. The pumps push water through large pipes called transmission mains, which transport large volumes to strategically located water storage reservoirs and pump stations. The water is then transported to smaller water mains that are used to deliver water to customers and fire hydrants.

Water quality services

Professional chemists, microbiologists and aquatic biologists staff the water quality laboratories in both treatment plants. They monitor the quality of the source water that enters both the Glenmore and Bearspaw treatment plants. This gives us important information about the quality of the water before it is treated and helps us adjust the level of treatment to produce safe drinking water.

The laboratory operates seven days a week, 365 days a year and analyzes samples for a wide range of parameters. The water samples are collected in the watershed (for early warning of changing river conditions); at every stage of the treatment process (to optimize treatment processes and meet regulatory requirements) and throughout Calgary’s water distribution system (to ensure public health).

When the quality of water changes or other unpredictable situations occur, staff increase the frequency of sample collection and analysis, and add additional monitoring sites.

This level of monitoring ensures that our drinking water consistently meets or exceeds all federal Health Canada guidelines and provincial standards set by Alberta Environment and Parks.